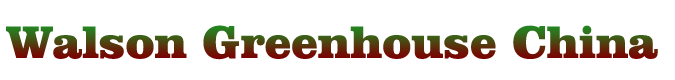

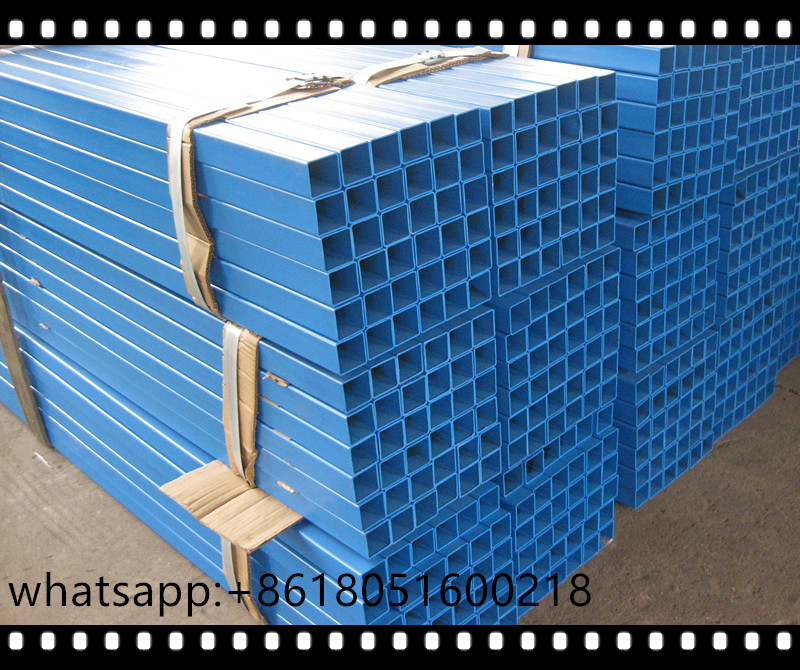

powder coated and paint pipe

Powder coated and Painted pipe

the pipe galvalized or not, then add powder coated or paint, make the pipes beautiful and long time for use.

any color is ok.

The Details Of the powder:

1. Tough, durable, lasting coating for metals

2. Excellent hardness and abrasion/impact resistance

3. Available colors

4. Health and Environmental Protection

5. Consistent color and appearance of the product

6. The ability to survive in highly corrosive environments

7. Flexibility to allow forming after coating

8. High durability

11. Resistance to chipping

12. Chemical resistant weather resistant

Powder coating technical parameters:

Physical Property:

Chemical property:

ATT: Above tests adopt 0.8mm deoiling and derusting cold-rolled steel sheets, coating film thickness 60~80um; performance index of coating film will change with brilliance changing.

Substrates Coated:

Powder coating Test:

Test Item:

The Performance:

the pipe galvalized or not, then add powder coated or paint, make the pipes beautiful and long time for use.

any color is ok.

The Details Of the powder:

1. Tough, durable, lasting coating for metals

2. Excellent hardness and abrasion/impact resistance

3. Available colors

4. Health and Environmental Protection

5. Consistent color and appearance of the product

6. The ability to survive in highly corrosive environments

7. Flexibility to allow forming after coating

8. High durability

11. Resistance to chipping

12. Chemical resistant weather resistant

Powder coating technical parameters:

| Item | Instrument | Standard | Testing method |

| Pencil hardness | Pencil hardness instrument | ≥ H | GB/6739 |

| Impact resistance | Impact tester | ≥ 50 kg.cm | GB/T 1732 |

| Flexing endurance | Bending instrument | ≤ 2mm | GB/T 6742 |

| Adhesive force | Cross-Cut tester | 0 grade | GB/T 9286 |

| Bulge | Bulge instrument | ≥ 6 mm | GB/T9753 |

Chemical property:

| Resistance to salt spray | ≥ 500 Hs | ≥ 9 grade | GB/T 1771 |

| Resistance to heat and humidity | ≥ 1000 Hs | Slight loss of gloss | GB/T 1740 |

Substrates Coated:

|

Cold Rolled/Hot Rolled Steel Galvanized Steel Iron Castings Zinc Castings Copper/Brass Magnesium |

Aluminum Extrusions and Castings Rare Earth Magnets (NdFeB) NiZn Plated Steel Stainless Steel Powder Metallurgy Parts Some Non-Metallics |

Test Item:

| Soluble heavy metals(EN71-3) | Pass |

| Formaldehyde emission(EN717-1:2004) | Pass |

| Lead content(16-CFR1303) | Pass |

| Food testing(V.S.21CFR/F.D.A) |

Pass |

|

The salt spray resistance is a great breakthrough compared with electroplating products. Salt spray test |

48H(500H available) |

| Impact resistance(GB/T1732-1993) | 30KG.CM |

| Adhesion (GB/T9286-1998) | GTO(BEST) |

|

UV resistance ASTM G154-06 ISO105-A02:1993 For the corrosion resistance of plated nickel, plated chrome, plated brass, plated copper and plated tin products. |

Available |

Contact: +86 18051600218 or gomesteel@163.com

Enquire now